Polyethylene Tubing

Polyethylene tubing is a cost-effective range for the general purpose transfer of laboratory liquids. It exhibits some similar properties to PTFE tubing such as rigidity, but some reduced functionality which is reflected in the cost. For example, the working temperature range and environmental resilience is more confined than in PTFE tubing.

It is quite inert, having low impact on the fluids passing though it. This combined with its purity make it ideal for use in corrosive atmospheres or for food processing. The thin wall of Polyethylene tubing allows easy visual inspection of the contents and flow. Polyethylene is usually supplied as very small diameter tubing.

Polyethylene tubing is not suitable for peristaltic pump use.

The material contains no Substances of Very High Concern (SVHCs) as classified by the REACH environmental regulation.

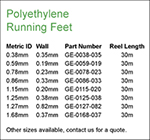

Polyethylene Tubing Bridge Charts

Polyethylene Tubing General Product Information

Product

- Low Density Polyethylene (LDPE)

Full Name

- Polyethylene

Application

- General Laboratory Instrumentation Links

- Low Pressure and Low Temperature Applications

- Corrosive Atmosphere Installations

Characteristics

- Soft, Non-Toxic

- Wide Chemical Resistance

- Suitable for Food Contact

- Translucent

Temperature Range

- -70°C to +80°C (-94°F to +112°F)

Sterilizations

- Ethylene Oxide

Hardness

- 48 Shore D

Elongation at Break

- 300% – 750%

Certification

- FDA Compliant